With the anticipated arrival of the new GR GT—a dedicated, high-performance machine—Toyota is making a definitive return to the halo supercar segment. This move echoes the brand’s legendary efforts with the Jag E-Type-esque 2000GT in 1967 and the technologically sublime Lexus LFA in 2010. However, the formula this time is profoundly different. Instead of relying on the naturally aspirated inline-six or V-10 engines of its predecessors, Toyota is embracing the modern supercar standard: a potent 4.0-liter twin-turbo V-8, critically enhanced by the brand’s hallmark expertise in hybridization.

While Toyota has warned that detailed information will be strategically released over the coming months, a wealth of critical technical details have already been admitted, observed, or discovered through industry insights. This article compiles everything currently known about the engine that will power Toyota’s new flagship, revealing a highly sophisticated, bespoke design aimed squarely at dominating the performance landscape.

🧱 Engine Architecture: Bespoke and Oversquare

In an era where many manufacturers, notably BMW and Mercedes, create their V-8 engines by essentially combining two ubiquitous 2.0-liter four-cylinder blocks onto a common crankshaft, Toyota has chosen a different, more dedicated path.

Not Based on the G20E Family

Toyota’s new aluminum-block 4.0-liter V-8 is not derived from the company’s latest family of smaller engines, the 1.5–2.0-liter G20E series. Instead, it is understood to be derived from a specialized V-8 unit originally developed for the now-canceled Lexus LC F performance project. This foundational heritage suggests a design inherently focused on high-output performance rather than cost efficiency or parts commonality.

The Oversquare Design Advantage

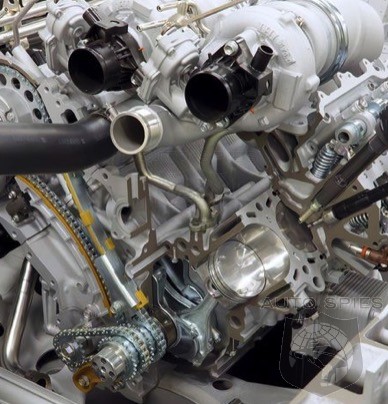

The engine adopts a 90-degree V-8 configuration and utilizes a significantly oversquare geometry. This is achieved by drastically reducing the stroke compared to the G20E’s 97.6 mm dimension, settling at a short 83.1 mm. Simultaneously, the bore is enlarged from 80.5 mm to a wide 87.5 mm.

The resulting oversquare bore-to-stroke ratio is a crucial indicator of the engine’s intended performance characteristics. An oversquare design generally facilitates higher revving capability—a trait highly desirable in a supercar engine—by reducing piston speed and allowing for larger valve sizes to improve airflow. This strategy aligns with the design principles seen in purebred performance engines like the McLaren M840T (93.0 x 73.5 mm), contrasting with the undersquare (long-stroke) setups favored by some competitors, such as Mercedes (83.0 x 92.0 mm) and the VW Group (84.5 x 89.0 mm), which often prioritize low-end torque.

Furthermore, sources indicate the V-8 will feature forged internal components, including the connecting rods, pistons, and the cross-plane crankshaft. Forged components provide superior strength and durability, essential for handling the extreme forces generated by high boost pressures and prolonged high-RPM track use.

⚡ Performance Targets: Power and Torque

Toyota has officially announced ambitious, yet conservative-sounding, total-system output figures for the GR GT’s powertrain, combining the twin-turbo V-8 and the electric motor.

The claimed total-system target is 641 horsepower (hp) and 627 pound-feet (lb-ft) of torque.

Given Toyota’s history of conservative ratings and the context of their other engine offerings, these figures are likely to represent a minimum or a specific Lexus state of tune (potentially for an upcoming related model). For perspective, Toyota’s high-output four-cylinder engines are already said to be capable of around 400 hp and 400 lb-ft of torque in street trim. An engine with double the cylinders plus a dedicated hybrid motor is expected to exceed the 641 hp mark when fully unleashed in its flagship GR GT application. The combination suggests a powertrain that will offer blistering acceleration and immense mid-range punch.

🔥 Cutting-Edge Technology: Hot-V, Injection, and Lubrication

The 4.0-liter V-8 incorporates several state-of-the-art design features, placing it firmly among the most technologically advanced powerplants in the world.

The Hot-V Arrangement

Following the trend set by leading European performance houses, Toyota has adopted a “hot-vee” or “hot-V” turbocharger configuration. In this design, the exhaust manifolds exit directly into the valley (the “V”) between the two cylinder banks, where the twin turbochargers are centrally mounted.

This layout offers two major advantages:

- Reduced Turbo Lag: The path from the exhaust ports to the turbine blades is dramatically shortened, improving throttle response and reducing turbo lag.

- Packaging Efficiency: The bulky turbochargers are tucked into the empty space atop the engine, making the engine narrower and easier to package lower in the chassis.

The pressurized intake air is then directed to intercoolers before being routed back into the cylinder heads, where the exhaust manifolds would traditionally reside (a reverse-flow head design). Notably, visual inspection of the engine’s cutaway does not show the orange high-voltage wires associated with electrified turbochargers, suggesting these are conventional, non-electrified turbo units, unlike those used on vehicles such as the Porsche Panamera Turbo E-Hybrid.

D-4 Port- and Direct-Injection System

Cutaway illustrations confirm the use of Toyota’s sophisticated D-4 injection system. This system utilizes dual fuel injectors per cylinder: one located in the traditional intake port and a second high-pressure injector positioned directly inside the combustion chamber (direct injection).

The D-4 system allows the engine control unit (ECU) to use either the port injector, the direct injector, or both simultaneously, optimizing fuel delivery based on operating conditions:

- Direct Injection (High Load/Speed): Provides evaporative cooling, suppressing knock, and allowing for higher compression ratios and boost pressures.

- Port Injection (Low Load/Speed): Helps keep the intake valves clean and improves fuel atomization for cleaner cold starts and lower emissions.

It is also apparent from these cutaways that Toyota is not implementing a pre-chamber ignition system, a technique seen in engines like the Maserati Nettuno, favoring instead a conventional spark-plug ignition strategy paired with the highly effective D-4 injection.

Dry-Sump Lubrication

To help fit this “big honking V-8” under the GR GT’s sleek, low hood line, Toyota is utilizing a dry-sump lubrication system.

Unlike a conventional wet-sump system, where oil is stored in a pan beneath the crankshaft, the dry-sump system stores oil in a remote reservoir. This configuration offers several performance benefits:

- Lower Engine Mounting: Eliminating the deep oil pan allows the engine to be mounted lower in the chassis, significantly improving the vehicle’s center of gravity (CG).

- Consistent Oil Supply: Multi-stage scavenge pumps actively extract oil from the crankcase (aided by a specially thinned oil pan) and ensure oil pressure remains stable during high-G maneuvers (hard cornering, acceleration, and braking) typical of track use, preventing oil starvation.

- Increased Oil Capacity: The external reservoir allows for a much larger total oil capacity, which is crucial for enhanced cooling and durability during sustained high-performance track driving.

⚙️ The Hybrid Backbone: Transaxle and Weight Balance

The hybridization of the powertrain is not simply a bolt-on feature but an integral component of the GR GT’s dynamic strategy, impacting both performance and chassis balance.

Rear-Mounted Transaxle for Optimal Balance

A key objective for the GR GT’s architecture is achieving a near-perfect weight distribution, specifically a targeted 45/55 front/rear weight balance. To accomplish this, the transmission—an eight-speed planetary automatic—is mounted at the rear axle, creating a transaxle setup.

This rear-mounted transmission is rigidly connected to the front-mounted V-8 engine via a lightweight carbon-fiber torque tube. This tube encases the driveshaft, providing enhanced structural rigidity and minimizing torsional flexing between the engine and the transaxle.

Integrated Hybrid Motor

The crucial element of the hybrid system is integrated directly into the transaxle housing. The electric motor is located just ahead of the transmission gearing.

In place of a conventional torque converter, the system utilizes a wet-clutch launch device, similar to high-performance setups used by certain AMG models. This clutch assembly facilitates smooth gear changes and efficient coupling of the engine and electric motor. The electric motor, situated immediately behind the launch clutch, provides instant torque fill, supplementary power, and regenerative braking capability.

At this time, detailed information regarding the specific battery chemistry (e.g., lithium-ion, solid-state) or the total storage capacity (kWh) of the hybrid battery pack remains undisclosed, pending future information releases.

🏁 Conclusion: A Supercar Contender

The technical revelations surrounding Toyota’s new 4.0-liter twin-turbo V-8 for the GR GT solidify the brand’s intent to compete at the very pinnacle of the supercar segment. By developing a bespoke, oversquare engine with forged internals, adopting the efficiency and performance of a hot-V design, utilizing advanced D-4 dual injection, and integrating a dry-sump system for low CG, Toyota is not merely entering the race—it is setting a new benchmark. Coupled with the performance-enhancing and balance-optimizing rear-mounted hybrid transaxle, the GR GT is poised to become a technological marvel and a true successor to the legendary 2000GT and LFA. The dribble of information will continue, and the automotive world remains eagerly tuned in for the full reveal of this radical new machine.

Tinggalkan Balasan